Material Specification

Material Specification

We offers a superlative metal casting experience in an environment that is unparalleled by others. The goal is to applying practical concepts that will prepare them for a future in the manufacturing industry. To achieve this our lab is equipped with machinery, tooling, hardware, and software to help students design, produce and test a wide range of cast metals and cast metal matrix composites.This lab allows for the custom formulations of alloys. Our team use the following techniques to analyse these alloys, minimizing problems in casting defects and maximizing aesthetic qualities.

Grey Iron

| UNITED KINGDOM | BS 1452:197 | ||||

|---|---|---|---|---|---|

| ASTM A 48 CLASS | GRADE | DIA OF THE CAST TEST BAR | N/mm² | kgf/mm² | tonn/in² |

| 21.80 | 150 | 30–32 | 150 | 15.3 | 9.7 |

| 26.09 | 180 | 30–32 | 180 | 16.4 | 11.7 |

| 31.95 | 220 | 30–32 | 220 | 22.4 | 14.2 |

| 37.68 | 260 | 30–32 | 260 | 26.5 | 16.8 |

| 43.55 | 300 | 30–32 | 300 | 30.6 | 19.4 |

| 50.72 | 350 | 30–32 | 350 | 35.7 | 22.7 |

| 57.97 | 400 | 30–32 | 400 | 40.8 | 25.9 |

Grey Iron

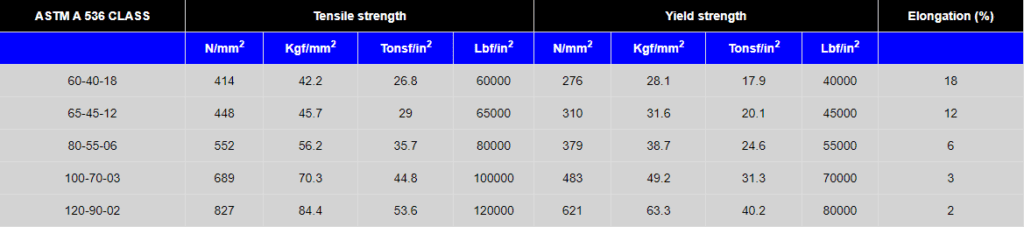

S.G Iron

| ASTM A 536 CLASS | Tensile strength | Yield strength | Elongation (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| N/mm² | kgf/mm² | tons/in² | lbf/in² | N/mm² | kgf/mm² | tons/in² | lbf/in² | ||

| 60-40-18 | 414 | 42.2 | 26.8 | 60000 | 276 | 28.1 | 17.9 | 40000 | 18 |

| 65-45-12 | 448 | 45.7 | 29 | 65000 | 310 | 31.6 | 20.1 | 45000 | 12 |

| 80-55-06 | 552 | 56.2 | 35.7 | 80000 | 379 | 38.7 | 24.6 | 55000 | 6 |

| 100-70-03 | 689 | 70.3 | 44.8 | 100000 | 483 | 49.2 | 31.3 | 70000 | 3 |

| 120-90-02 | 827 | 84.4 | 53.6 | 120000 | 621 | 63.3 | 40.2 | 80000 | 2 |

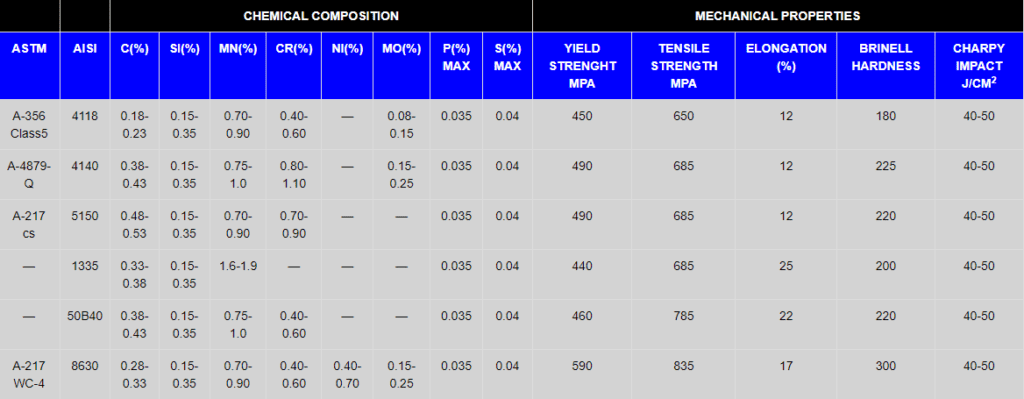

Low Alloy Steel

| CHEMICAL COMPOSITION | MECHANICAL PROPERTIES | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM | AISI | C (%) | Si (%) | Mn (%) | Cr (%) | Ni (%) | Mo (%) | P (%) Max | S (%) Max | YIELD STRENGTH (MPa) | TENSILE STRENGTH (MPa) | ELONGATION (%) | BRINELL HARDNESS | CHARPY IMPACT |

| — | 1015 | 0.13–0.18 | 0.4 | 0.3–0.6 | — | — | — | 0.04 | 0.05 | 270 | 450 | 25 | 120 | 90 |

| A-356 Class5 | 4118 | 0.18–0.23 | 0.15–0.35 | 0.70–0.90 | 0.40–0.60 | — | 0.08–0.15 | 0.035 | 0.04 | 450 | 650 | 12 | 180 | 40–50 |

| A-4879-Q | 4140 | 0.38–0.43 | 0.15–0.35 | 0.75–1.0 | 0.80–1.10 | — | 0.15–0.25 | 0.035 | 0.04 | 490 | 685 | 12 | 225 | 40–50 |

| A-217 CS | 5150 | 0.48–0.53 | 0.15–0.35 | 0.70–0.90 | 0.70–0.90 | — | — | 0.035 | 0.04 | 490 | 685 | 12 | 220 | 40–50 |

| — | 1335 | 0.33–0.38 | 0.15–0.35 | 1.6–1.9 | — | — | — | 0.035 | 0.04 | 440 | 685 | 25 | 200 | 40–50 |

| — | 50B40 | 0.38–0.43 | 0.15–0.35 | 0.75–1.0 | 0.40–0.60 | — | — | 0.035 | 0.04 | 460 | 785 | 22 | 220 | 40–50 |

| A-217 WC-4 | 8630 | 0.28–0.33 | 0.15–0.35 | 0.70–0.90 | 0.40–0.60 | 0.40–0.70 | 0.15–0.25 | 0.035 | 0.04 | 590 | 835 | 17 | 300 | 40–50 |

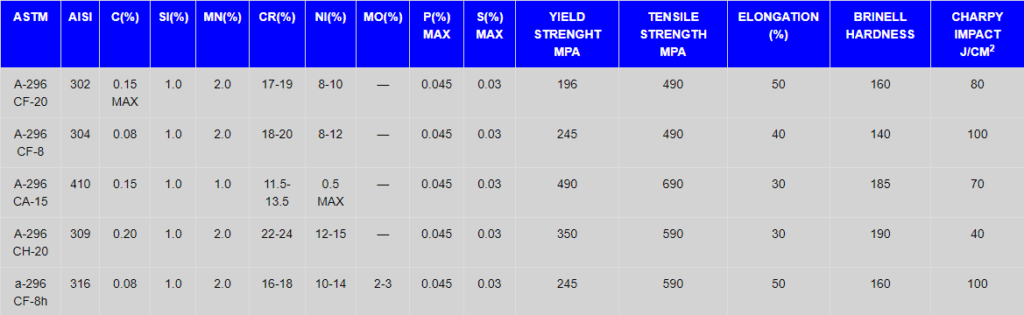

Corrosion Resisting Steel

| ASTM | AISI | C(%) | Si(%) | Mn(%) | Cr(%) | Ni(%) | Mo(%) | P(%) Max | S(%) Max | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Brinell Hardness | Charpy Impact (J/cm²) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A-296 CF-20 | 302 | 0.15 Max | 1.0 | 2.0 | 17–19 | 8–10 | — | 0.045 | 0.03 | 196 | 490 | 50 | 160 | 80 |

| A-296 CF-8 | 304 | 0.08 | 1.0 | 2.0 | 18–20 | 8–12 | — | 0.045 | 0.03 | 245 | 490 | 40 | 140 | 100 |

| A-296 CA-15 | 410 | 0.15 | 1.0 | 1.0 | 11.5–13.5 | 0.5 Max | — | 0.045 | 0.03 | 490 | 690 | 30 | 185 | 70 |

| A-296 CH-20 | 309 | 0.20 | 1.0 | 2.0 | 22–24 | 12–15 | — | 0.045 | 0.03 | 350 | 590 | 30 | 190 | 40 |

| A-296 CF-8h | 316 | 0.08 | 1.0 | 2.0 | 16–18 | 10–14 | 2–3 | 0.045 | 0.03 | 245 | 590 | 50 | 160 | 100 |

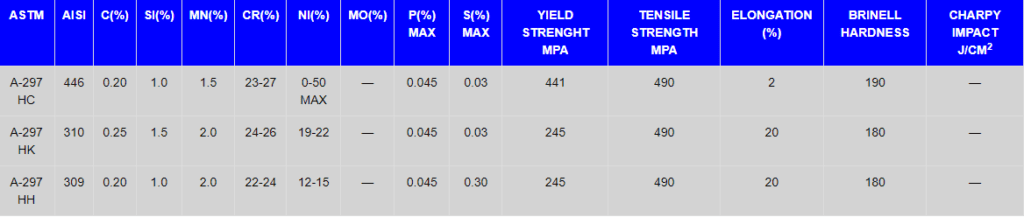

Heat Resisting Steel

| ASTM | AISI | C(%) | Si(%) | Mn(%) | Cr(%) | Ni(%) | Mo(%) | P(%) Max | S(%) Max | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Brinell Hardness | Charpy Impact (J/cm²) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A-297 HC | 446 | 0.20 | 1.0 | 1.5 | 23–27 | 0–50 Max | — | 0.045 | 0.03 | 441 | 490 | 2 | 190 | — |

| A-297 HK | 310 | 0.25 | 1.5 | 2.0 | 24–26 | 19–22 | — | 0.045 | 0.03 | 245 | 490 | 20 | 180 | — |

| A-297 HH | 309 | 0.20 | 1.0 | 2.0 | 22–24 | 12–15 | — | 0.045 | 0.30 | 245 | 490 | 20 | 180 | — |

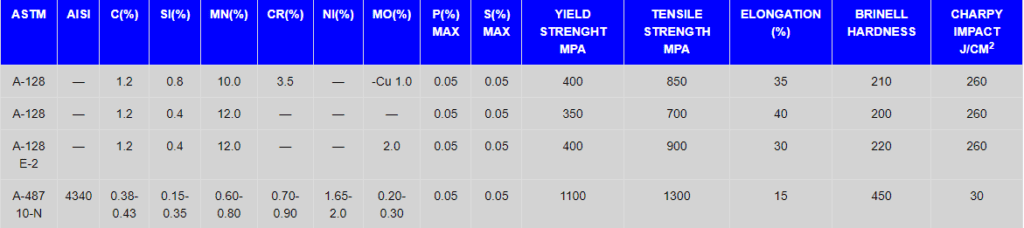

Wear Resisting Steel

| ASTM | AISI | C(%) | Si(%) | Mn(%) | Cr(%) | Ni(%) | Mo(%) | P(%) Max | S(%) Max | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Brinell Hardness | Charpy Impact (J/cm²) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A-128 | — | 1.2 | 0.8 | 10.0 | 3.5 | — | Cu 1.0 | 0.05 | 0.05 | 400 | 850 | 35 | 210 | 260 |

| A-128 | — | 1.2 | 0.4 | 12.0 | — | — | — | 0.05 | 0.05 | 350 | 700 | 40 | 200 | 260 |

| A-128 E-2 | — | 1.2 | 0.4 | 12.0 | — | — | 2.0 | 0.05 | 0.05 | 400 | 900 | 30 | 220 | 260 |

| A-487 10-N | 4340 | 0.38–0.43 | 0.15–0.35 | 0.60–0.80 | 0.70–0.90 | 1.65–2.0 | 0.20–0.30 | 0.05 | 0.05 | 1100 | 1300 | 15 | 450 | 30 |

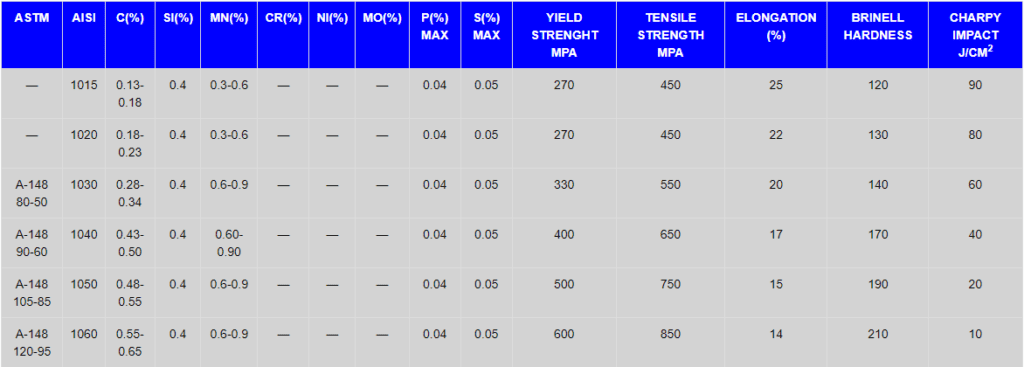

Carbon Steel

| ASTM | AISI | C (%) | Si (%) | Mn (%) | Cr (%) | Ni (%) | Mo (%) | P (%) Max | S (%) Max | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Brinell Hardness | Charpy Impact (J/cm²) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| — | 1015 | 0.13–0.18 | 0.4 | 0.3–0.6 | — | — | — | 0.04 | 0.05 | 270 | 450 | 25 | 120 | 90 |

| — | 1020 | 0.18–0.23 | 0.4 | 0.3–0.6 | — | — | — | 0.04 | 0.05 | 270 | 450 | 22 | 130 | 80 |

| A-148 80-50 | 1030 | 0.28–0.34 | 0.4 | 0.6–0.9 | — | — | — | 0.04 | 0.05 | 330 | 550 | 20 | 140 | 60 |

| A-148 90-60 | 1040 | 0.43–0.50 | 0.4 | 0.60–0.90 | — | — | — | 0.04 | 0.05 | 400 | 650 | 17 | 170 | 40 |

| A-148 105-85 | 1050 | 0.48–0.55 | 0.4 | 0.6–0.9 | — | — | — | 0.04 | 0.05 | 500 | 750 | 15 | 190 | 20 |

| A-148 120-95 | 1060 | 0.55–0.65 | 0.4 | 0.6–0.9 | — | — | — | 0.04 | 0.05 | 600 | 850 | 14 | 210 | 10 |